Are you presently knowledgeable about the procedure of Rotational Molding, sometimes called Rotomolding? It is a plastic material production approach that’s existed since the 1940s, but it’s in recent years that it’s truly transformed the marketplace. In this post, we will discover the science and art behind Rotational Molding, take a look at the advantages it includes manufacturers of plastic items, and take into account the position it plays in sustainability and environment obligation.

Exactly what is Rotomolding?

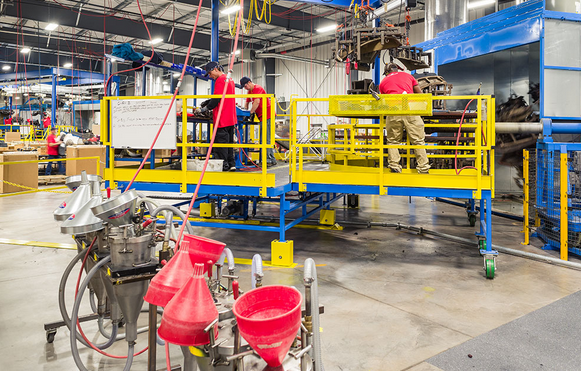

Rotational Molding, or Rotomolding as it’s commonly abbreviated, is actually a plastic producing method that involves melting plastic natural powder in a hollow mold, turning the fungus continually, after which enabling the plastic material to great and firm up. Rotomolding is really a exclusive method that produces merchandise with solid, durable, and consistent walls of regular fullness. The rotational approach ensures that every elements of the mold will receive the same quantity of molten plastic, which leads to its all round consistency.

Benefits associated with Rotomolding:

One of the more important benefits associated with Rotomolding is being able to produce huge, sophisticated forms and parts. Contrary to other plastic-type manufacturing tactics, Rotomolding has no sizing limits, making it perfect for developing large-size goods, such as tanks, boxes, and playground equipment. An additional benefit is the cabability to manufacture hollow components without the use of seams or joints, decreasing the chances of water leaks or ruptures. Rotomolding is likewise highly adaptable regarding the forms of plastic-type material resins which can be used in the process, which include polyethylene, polypropylene, and nylon material.

Sustainability and Enviromentally friendly Obligation:

Rotomolding is really a truly environmentally friendly producing technique that features a small environmental affect. Contrary to shot molding, as an example, Rotomolding works with a significantly lower volume of power and generates much less waste materials. In addition, many of the resources applied along the way are recyclable, to enable them to be repurposed once the product or service reaches the end from the lifecycle. Provided that Rotomolding creates extremely long lasting components, the merchandise made throughout the process are likely never to end up in landfills in the near future. For that reason, the method by itself, and the goods manufactured via it, are both significant contributors to environment and monetary sustainability.

simple

Rotomolding is really a flexible and revolutionary production method that offers enormous advantages to suppliers, customers, along with the atmosphere equally. As client desire will grow for environmentally-pleasant and sustainable merchandise, it is likely that we will see increasingly more firms following the Rotomolding approach. By purchasing the art and science of Rotomolding, we can easily reinvent the plastic material market, producing products which are strong, cost-effective, and eco-warm and friendly.